Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

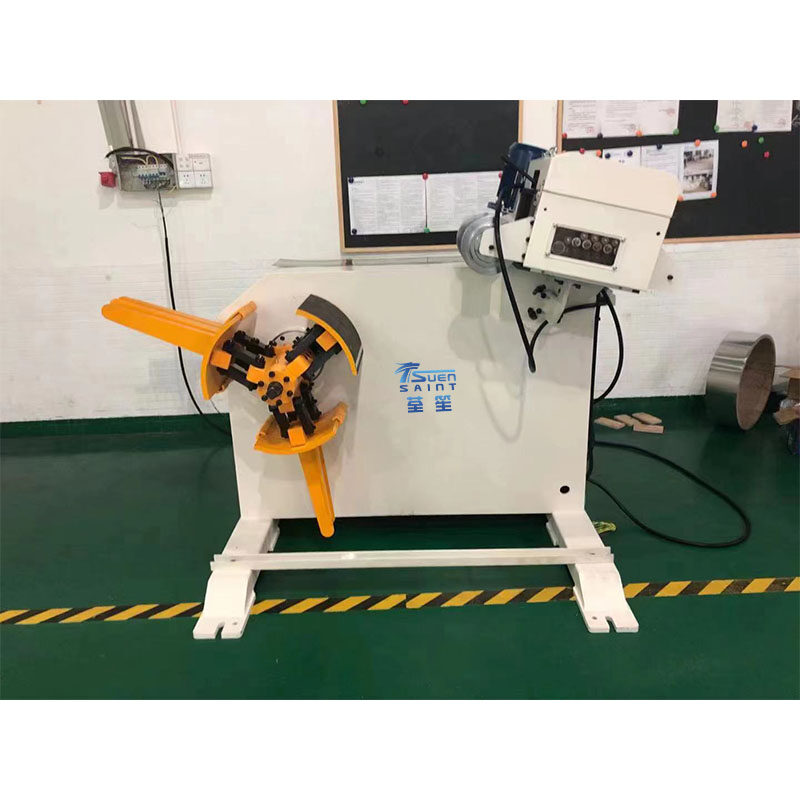

Uncoiler Straightener Feeder For Punching Machine

The uncoiler straightener feeder for punching machines stands as a pinnacle of engineering excellence, seamlessly marrying precision and efficiency in material feeding for metalworking. Meticulously designed, this integrated system transforms the mundane into an art, synchronizing uncoiling, straightening, and feeding processes. Its fluid operation ensures a continuous and uninterrupted workflow, this not only optimizes productivity but redefines the very essence of efficiency in the intricate realm of metal punching operations.

Uncoiler Straightener Feeder for Punching Machine

Product Description

Crafted exclusively for the punching machine industry, the uncoiler straightener feeder emerges as a bespoke solution, intricately designed to harmonize the intricate processes of uncoiling, straightening, and feeding. Its precision and integration redefine the landscape, ensuring an unbroken and regulated flow of metal sheets, fundamentally transforming the efficiency of the metalworking workflow.

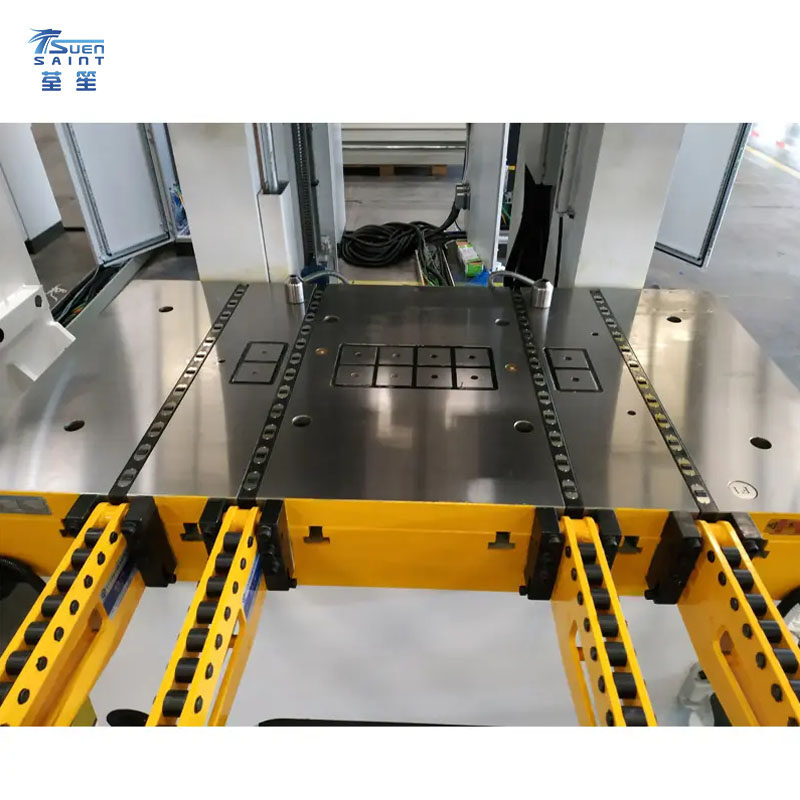

Product Features

Integrated Functionality: The system combines uncoiling, straightening, and feeding functions in a single unit, providing a comprehensive solution for material preparation in punching processes.

Adjustable Straightening Mechanism: Featuring an adjustable straightening mechanism, the system accommodates various metal sheet specifications, ensuring precise and uniform material straightening.

High-Speed Feeding: With a high-speed feeding mechanism, the uncoiler straightener feeder ensures a continuous and efficient supply of material to the punching machine, minimizing downtime and optimizing production rates.

Product Advantages

Reduced Setup Time: The uncoiler straightener feeder revolutionizes setup procedures by integrating uncoiling, straightening, and feeding functions seamlessly. This integration substantially reduces setup time, streamlining the entire process and minimizing downtime during material changes and die setups.

Enhanced Productivity: Equipped with high-speed feeding capabilities, the uncoiler straightener feeder ensures a continuous and efficient supply of material to the punching machine. This feature directly contributes to increased production rates, optimizing overall operational productivity.

Minimized Material Waste: The adjustable straightening mechanism within the system plays a pivotal role in minimizing material waste during punching operations. By ensuring precise and uniform material straightening, the system reduces the likelihood of errors and defects, ultimately leading to cost savings and resource efficiency.

Versatile Application: The uncoiler straightener feeder's modular design and adaptable features make it a versatile solution for various punching machine configurations and metal sheet specifications. Its flexibility ensures compatibility with diverse manufacturing setups and applications. Whether dealing with different machine types or varying metal sheet dimensions, the system can be easily configured to meet specific production requirements.